Carol Brower, Michael Schulte and Pradeep Haldar Custom Electronics, Inc.

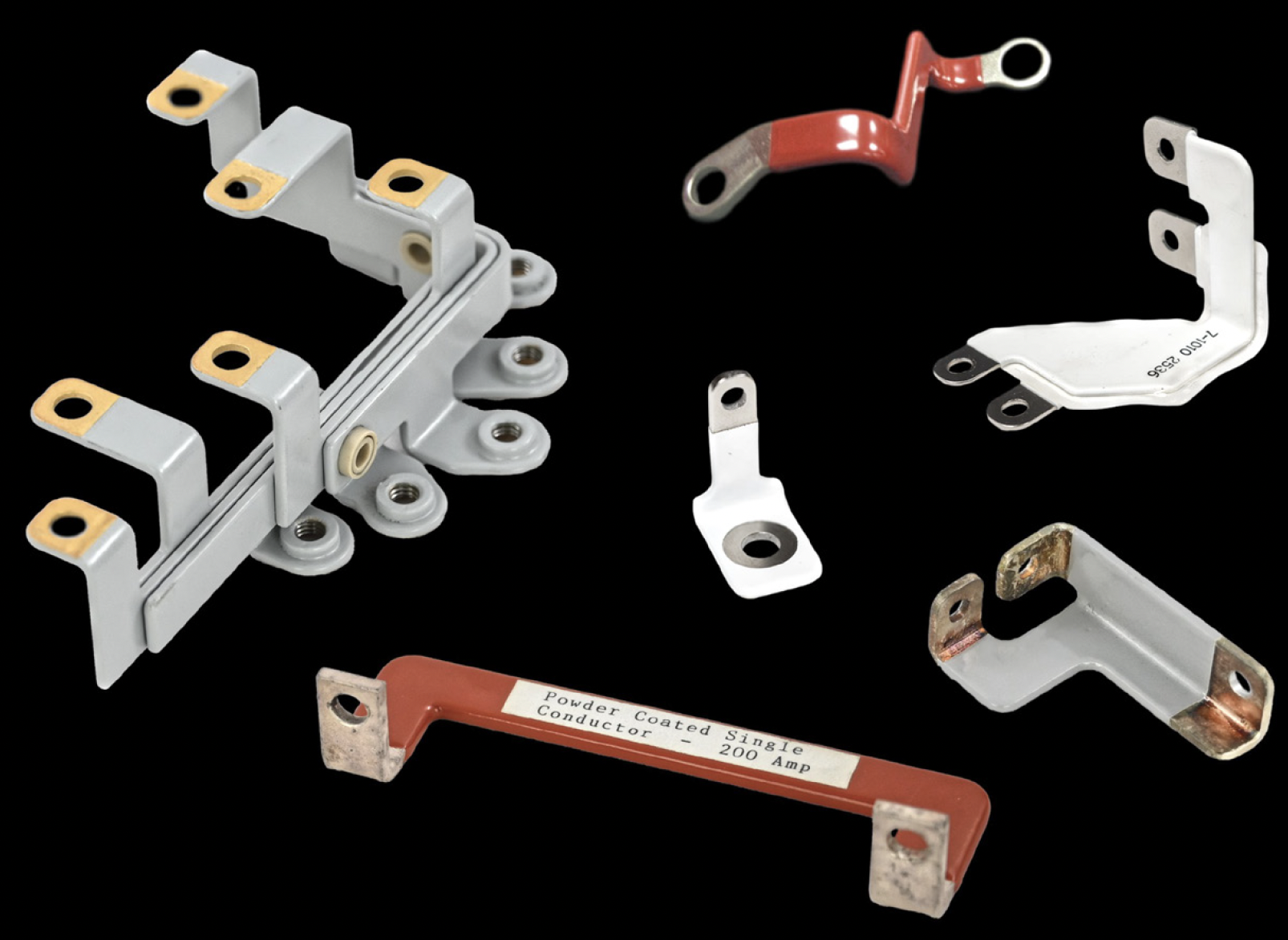

Powder-coated bus bars are increasingly critical for military satellite, spacecraft and defense power systems that demand compact, lightweight and reliable power distribution.

From enduring vacuums, thermal extremes and radiation in orbit, to shock and vibration in rugged battlefield deployments, powder coatings are an efficient method for insulating electrical and electronic components.

This solid, protective layer enhances the electrical insulation properties of various parts, including bus bars, transformers, motors and connectors.

Applied as a free-flowing, dry powder, these coatings are electrostatically charged and then cured under heat to form a smooth, hard finish.

Powder coatings provide excellent dielectric properties, making them ideal for insulating components in military platforms and satellite power systems.

The absence of solvents also reduces the risk of harmful emissions during application, making powder coatings environmentally friendly.

Additionally, they offer high resistance to corrosion, heat and moisture, which are critical for subcomponents operating in space or harsh defense environments.

Compared to other methods, such as liquid coatings and varnishes, powder coatings stand out for their durability and eco-friendliness.

Liquid coatings, while effective, often require the use of volatile organic compounds (VOCs) that can be harmful to both workers and the environment. Moreover, liquid coatings may require multiple layers and longer curing times, leading to increased production costs.

Often used in electrical insulation, varnishes provide a protective layer but might not offer the same level of corrosion or heat resistance as powder coatings. Additionally, varnishes can be prone to cracking over time, especially in high-temperature or vibration-heavy applications, such as rocket launches or in mobile battlefield systems.

By contrast, powder coatings provide a more uniform and robust finish. Overall, powder coatings offer superior performance in terms of durability, insulation and environmental impact when compared to other methods.

________________________________________

Highly Demanding Applications

________________________________________

Powder coatings are increasingly being applied to a variety of electrical and electronic subcomponents to enhance durability, insulation and environmental resistance.

Subcomponents like bus bars face high-performance demands that make powder coatings a key technology for improving their reliability and longevity in military, aerospace and satellite applications.

• Single Insulated Conductor

Custom-machined, formed and plated conductors

Bushings, connectors, other special hardware

installed by press fitting or soldering

Powder coated or heel-shrink insulation

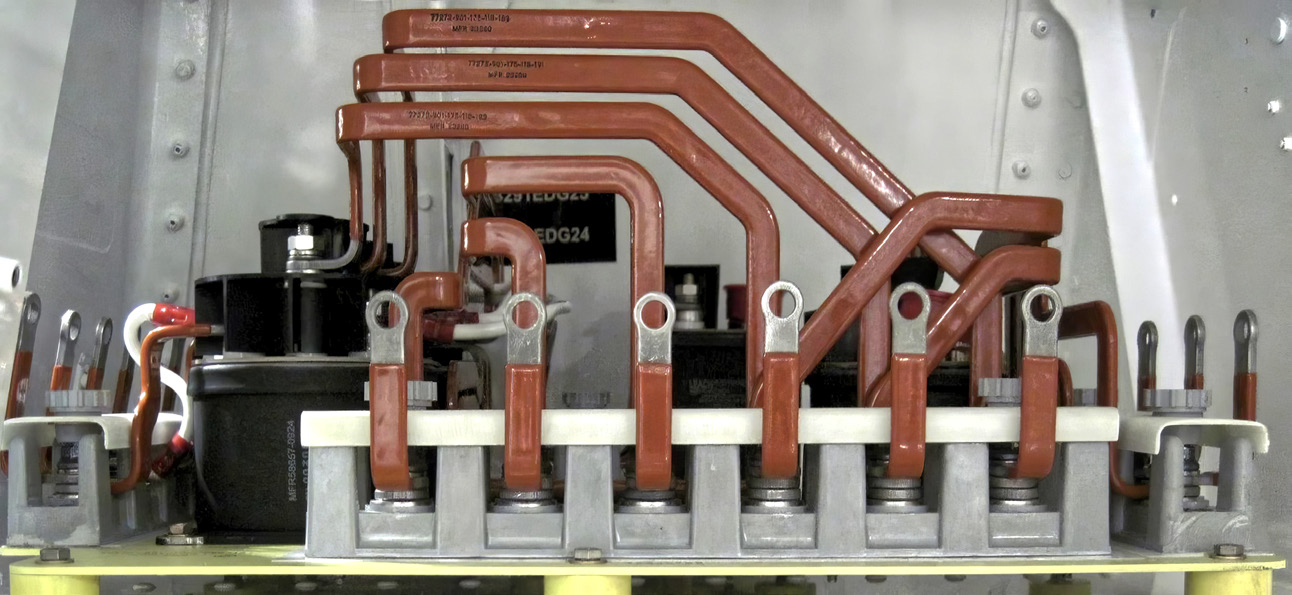

• Multi-lover Conductor

Two or more conductors insulated from one another

by dielectric material:

• Mylar®

• Kaplan®

• Nomex®

• GlO

• Custom shaped / lo,med then bonded together

using adhesive and/or mechanical system

• Variety of bushings, connector, and other

hardware installed

• Integrated Electronic Assemblies

Mulit-loyer bu, bar os,embly combined with a

group of CEI film capacitors

Designed and manufactured to meet customer's

specific electrical, mechanical, and environmental

requirements

• PCB StrongBor Stiffeners

Available in any length and various heights

Can be used as ground and/or power distribution

bus bars (up to 64 Amps} eliminating need for

heavy traces

Significantly stiffens PCB's helping the laminated

dielectric support its components

Bus bars are traditionally used for high-voltage power distribution in vehicles, aircraft, naval systems and satellite buses, where weight, space and environmental conditions are mission-critical. Powder coatings also provide added reassurance for insulation and protection against corrosion, vibrations and mechanical stress.

Due to their efficiency in conducting electricity at high voltages, bus bars are increasingly replacing traditional wiring in critical applications, such as satellite power buses, ground station electronics and advanced defense systems, while also maintaining a compact form factor.

Bus bars, made of copper or aluminum, offer superior electrical conductivity, especially where launch vibrations, thermal cycling and radiation can challenge system integrity.

To enhance performance and longevity in challenging conditions, powder coatings have emerged as a key technology. These coatings improve the durability of bus bars as well as provide insulation, corrosion resistance and protection from environmental factors, including vacuum conditions, atomic oxygen exposure in orbit and battlefield shock or vibration.

Enhanced Insulation

In high-voltage systems, insulation is paramount to preventing short circuits and electrical failures. Powder coatings ensure that even in applications with fluctuating satellite power levels or high voltage defense systems, the bus bars remain adequately insulated, reducing the risk of electrical failures and improving mission safety.

Resistance to Vibrations and Mechanical Stress

One of the key advantages of powder coatings is their ability to withstand vibrations and mechanical stress, which are common in rocket launches, UAV maneuvers and rugged defense vehicles.

Corrosion and Environmental Protection

Bus bars are often exposed to harsh environmental conditions, including humidity, chemicals and extreme temperatures, which can lead to corrosion and reduced conductivity. Powder coatings are highly resistant to corrosion and oxidation, protecting the metal surfaces from moisture during ground handling, salt spray in naval applications or extreme temperature fluctuations in space.

Compact and Lightweight Designs

Space and weight are often at a premium in military systems, especially satellite platforms, UAVs and military vehicles.

Powder-coated bus bars and subcomponents allow for more compact and lightweight electrical distribution systems that reduce payload mass and improve efficiency. This is a key benefit to both satellite launches and mobile defense operations.

Powder-coated bus bars and subcomponents provide an ideal solution for military and satellite power architectures, offering enhanced durability, insulation and resistance to harsh environments. Their ability to withstand the rigors of space flight and defense missions makes them an essential technology for reliable power distribution in critical operations.

customelec.com/bus-bars