Space systems acquisitions for national security have always been very challenging. It literally is rocket science! Our ability to truly leverage the advantages that the space domain offers has always depended on the availability of state-of-the-art technology to apply to our space capabilities.

The level of requisite technology has demanded top-dollar investment and zero tolerance for errors. One small flaw in a launch vehicle can result in complete loss of the space vehicle. One small flaw in the space vehicle can result in total loss of mission on orbit. If not done correctly, the launch of a satellite is an irreversible process with dire and prohibitively expensive consequences. From the days of the “Schoolhouse Gang” led by General Bernard Schriever to the Space and Missile Systems Center of 2013, space acquisition has always required a team of dedicated, technically competent professionals and a significant dollar investment.

Although there are many constants about space acquisition, there are also some significant changes about the environment of the twenty-first century that compel us to evolve the way we acquire our space systems. The national security environment of 2013 is vastly different than that of 1947, or even that of 2005.

First and foremost, our space systems are absolutely critical to our national security operations today. The world relies on space-based capabilities to provide humanitarian help in the aftermath of natural and technological disasters such as the Indian Ocean tsunami, the Kashmir earthquake, and the Japanese nuclear reactor incident to assess damage and evaluate the situation on the ground. Space-based capabilities provide rapid mapping and high-resolution imaging that have become important support tools in emergency relief operations. The capabilities also aid in executing logistics, staff security, distribution, transportation, and setup of telecommunication networks and refugee camps.

We also have a growing dependence on space-based capabilities for our military combat operations. Immediately after the terrorist attacks of 2001, small groups of elite American military units were deployed to Afghanistan to support the anti-Taliban Afghan fighters. Those units carried 2.75-pound precision lightweight Global Positioning System (GPS) receivers as well as satellite-based communication devices they used to pinpoint enemy targets and call in devastating air strikes against them. Because GPS-guided munitions strike with such accuracy, they greatly reduce the number of air sorties needed to destroy a target. This is a far cry from the Vietnam War when Soldiers would look at a map to call in friendly and enemy coordinates and then pop smoke so the aircraft could know where they were! Whether it is humanitarian operations in support of tsunami relief or combat operations in Afghanistan, we cannot accomplish the mission without our space capabilities.

Another change is the fact that the physical environment in which our satellites and space systems must operate is now competitive, congested, and contested. Currently, more than 60 countries, or consortia, are operating satellites, and citizens of 39 nations have actually flown in space. Of the 190-plus countries around the globe, over 120 now own at least part of a satellite. There are more than 1,000 active satellites in orbit today.

In addition, the total amount of space debris has increased considerably in the past six years, primarily due to two events. The first was in 2007 when the Chinese tested an antisatellite weapon against one of their weather satellites. That test created more than 3,000 pieces of trackable debris along with thousands of pieces of debris too small to track—objects that will threaten other satellites for decades, if not centuries, to come.

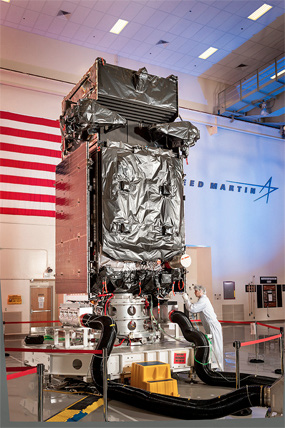

Artistic rendition of an AEHF satellite. Image courtesy of Lockheed Martin.

The second event was in 2009 when a dead Russian communications satellite hit an Iridium satellite, scattering about another 2,000 pieces of trackable debris around the Earth and, again, many more pieces too small to track. Even more troublesome are the estimated hundreds of thousands of small pieces of debris we cannot track in space today. Traveling at nearly 18,000 miles per hour, an object does not have to be very large to create havoc for fragile satellites. Furthermore, the cyber domain is becoming a realm of possibly devastating attacks on our space assets.

Lastly, the budgets available for acquiring and maintaining space systems are declining. We have traditionally focused our decisions about space systems exclusively on performance first, schedule second, and costs a distant third. We can no longer afford to do that. Affordability needs to be in the forefront of our acquisition planning and requirements discussions. This changing landscape provides both challenges and opportunities for space acquisition.

Mandates For Space Systems Acquisitions

This environment drives three mandates for space system acquisitions today.

First, we must continue to deliver on the space capabilities in the pipeline today. After several years (sometimes a decade or more) of development of these satellites and space systems, it is time to capitalize on that investment. We must consistently complete the build of these satellites and associated systems, safely and assuredly launch them into orbit, and turn over operations to Fourteenth Air Force.

Second, we must aggressively pursue opportunities to make these systems more affordable. We must ensure that we explore options to drive down costs as well as streamline and lean out our production and oversight mechanisms. In short, we make sure that every dollar counts. Certainly, we must maintain high standards for mission assurance. However, we must also make sure that we are not spending money doing things that provide no value and do not contribute to mission assurance. We must challenge the adage “We’ve always done it that way.”

The fifth Wideband Global SATCOM (WGS-5) satellite is encapsulated inside a United Launch Alliance Delta 4 5-meter diameter payload fairing prior to its launch from Cape Canaveral Air Force Base, Florida. Photo is courtesy of Pat Corkery, United Launch Alliance.

Third, we must explore new architectures and constructs for providing space capability in the future. We must reassess our basic architectures and employment concepts against the changing threat environment, respond to the challenges, and leverage the opportunities presented by the competitive, congested, and contested space domain.

Our current space acquisition strategy and programs confront these mandates head on. For protected satellite communications (SATCOM), we are on schedule to ship and launch the third Advanced Extremely High Frequency (AEHF) satellite in the fourth quarter of 2013. Soon, AEHF will have three operational satellites providing Earth coverage between 65 degrees north and 65 degrees south latitude. AEHF is scheduled to reach initial operational capability by June 2015, providing a 10-fold increase of communication throughput to the war fighter, compared to its Milstar predecessor.1

AEHF will provide more than 400 megabits per second (Mbps) of data-throughput capability as compared to Milstar’s 40Mbps. We will still continue to exploit Milstar’s capability, as AEHF satellites are backwards compatible and cross-linked with Milstar to provide an integrated, protected communications network for the United States and our allies. Canada, the Netherlands, and the United Kingdom are international partners to the program with planned initial operational capabilities in July 2013, March 2014, and May 2016, respectively.

For wideband communications, we launched the fifth Wideband Global SATCOM (WGS) in May 2013 and will declare full operational capability in early 2014. This will provide unprecedented wideband communications to U.S. and international partner users. We plan to launch the sixth WGS satellite in the fourth quarter of 2013. The WGS-6, which completes the three space vehicle (SV) buy for WGS Block II, is part of an international partnership whereby the Australian government purchased the SV in exchange for a certain percentage of bandwidth from the constellation.

Further down the pipeline, we are scheduled to launch WGS-7 in August 2015 to further augment the constellation. We also have plans for WGS 8–10 to deliver a new wideband digital channelizer that will almost double the capacity of the older systems. As was the case with WGS-6, international partners purchased WGS-9. New Zealand, Canada, Luxemburg, Denmark, and the Netherlands will get access to constellation bandwidth in return for their purchase of WGS-9.

The GPS IIF will complete production of its 12 satellites by the end of 2013. [At the time of this writing] we plan to launch one GPS IIF SV in October 2013, three SVs in 2014, two SVs in 2015, and the final two SVs in 2016.

We also expect the Next-Generation GPS Control Segment Block 1 to begin its transition to the operations process in 2016, providing GPS III SV launch and simulation as well as telemetry, tracking, and command capabilities. It will also enable GPS Blocks II and III on-orbit capability, including control of L1 C/A, L1 P(Y), L2 P(Y), L5, and L2C signals.2

Striving For Affordability

At the same time, we have a razor-sharp focus on making these systems more affordable. We have experienced shrinking budgets these past few years, and we have been finding innovative and creative solutions to be able to continue providing our war fighters and nation the space-based capabilities they depend on every day. We are changing our mind-set on our strategic and tactical outlook as we transition from development to production mode in a number of our programs. We’ve also reassessed many of our processes to ensure that we are as efficient as possible while maintaining mission assurance as our top priority.

Transition Programs from Development to Production

We have shifted from product development to production mode in several key programs, presenting many opportunities for us to make our systems more affordable. One example is in our Space-Based Infrared System (SBIRS) program with the second Geosynchronous Earth Orbit / Highly Elliptical Orbit (GEO/HEO) block (GEO/HEO 3–4) contract in 2008. Due to a 12-year gap between the GEO/HEO 1–2 block and the GEO/HEO 3–4 block contract awards, we’ve faced challenges with obsolescence, processes, and procedures, which increased government oversight and contractor interaction. However, these increased interactions led to production and cost-savings initiatives.

Artistic rendition of a GPS III satellite. Image courtesy of Lockheed Martin.

Our plan for GEO 5–6 continues our block-buy strategy to leverage economic order-quantity efficiencies, and it benefits from having all developmental spacecraft/ payloads delivered on orbit with the exception of a complete ground system. Although there are some challenges related to parts obsolescence that require initial nonrecurring engineering and advance procurement efforts, we can realize savings from using a fixed-price, firm target contract since we are now acquiring the fifth and sixth of its kind.

GPS III implements processes established during development. Currently, GPS III SV01 is in the process of completing development integration and testing, with an expected completion date in the second quarter of 2014. Meanwhile, GPS III SV02 is at the beginning of the production line. It began assembly, integration, and testing in July 2013. GPS III SV03 and SV04 are on contract and have begun assembly level production.

GPS III SV05–08 long-lead parts procurement is also on contract, with production contract award expected in 2013. Because we have firm requirements, design proven through developmental testing, established manufacturing processes, and qualified suppliers, GPS III made a great candidate for fixed-price-incentive firm request for proposal, which reduces contract data requirements lists (CDRL) from 115 to 20. AEHF is also firmly in the production phase. As with SBIRS, we are focused on satellite block buy and production practices to shorten schedules and lower the unit cost.

Introduce Lean Processing + Production Flow

We have introduced lean processing and production flow into many of our major programs to identify and realize efficiencies in the way we conduct business. Working with contractor Lockheed Martin, our AEHF program office proposed new production timelines for AEHF-5 and AEHF-6, reducing 73 months to 63.5 months and 71.5 months, respectively. We were able to simplify the process by eliminating multiple mechanical reconfigurations and vehicle repositionings and executing streamlined testing.

For SBIRS, we are striving to resolve the challenges we faced due to small production quantities and multiple gap years between contract awards by aligning new contract awards to the delivery of the previous block. This way, we may maintain a consistent production-floor team and processing capacity. For example, we can time the GEO 5–6 staffing ramp-up to coincide with the GEO/HEO 3–4 effort ramp-down to sustain a steady battle rhythm on our production floor.

More specifically within our SBIRS production efforts, we have implemented several initiatives to streamline flow and reduce costs. Our GEO-3 single-line flow production saved $4.3 million in real dollars! These savings were made possible by true team effort with collaboration across government, industry, and subcontractor team members. Together, we championed several efforts, including a series of 21 recommendations to reduce single-line flow production to about 70 days as well as streamlined vehicle assembly flow, mechanical operations, test preparation, and test execution. We saved additional dollars by reducing unit thermal cycles and powered vibration tests.3

We maintained a minimum of three thermal vacuum cycles for electronic/electromechanical units, with an average savings of about 18 hours per thermal cycle per unit and a reduction of four cycles. This saved three days on a schedule of 24/7 critical-path operation.

Furthermore, payload integrator Northrop Grumman reused GEO-3 hardware for the GEO-4 payload test, saving us $1.3 million. It used fully integrated Flight 3 Payload Control Assembly to test both GEO-3 and GEO-4 payloads. Doing so eliminated tasks such as packing and shipping of payload-control assembly boxes and reintegrating test units.

A Lockheed Martin engineer completes final preparations on SBIRS GEO-2 before the satellite’s shipment to Cape Canaveral Air Force Station, Florida. Photo is courtesy of Lockheed Martin.

For GPS IIF, we use a pulse-line production method based on lean processing and production principles.4 We continuously evaluate each of our four assembly and test work centers for rebalancing, ensuring that there is no production bottleneck at any one station. This has allowed a savings of 96 days in production from SV-4 to SV-5, the first two full-production GPS IIF SVs.

With GPS III, we have introduced and completed 59/59 (100 percent) manufacture-readiness design reviews to optimize build-process flow. We used 3-D modeling to digitally illustrate in real-time the manufacturing integration assembly and test hookup. This has reduced manufacturing work instruction by 70–83 percent.

Reduce + Eliminate Unnecessary Testing

We’ve further made our systems more affordable through reduction and elimination of unnecessary testing. By leveraging our lessons learned from the SBIRS GEO-1 campaign, we have reduced our GEO-2 planned duration by 55 percent to 105 days. Essentially, we were able to reduce development and testing for later iterations of software included in GEO-2. Whereas our system was unable to meet our suite of performance parameters until the fifth build for GEO-1, we are planning to achieve suitable performance using just three builds for GEO-2. We have also reduced the total number of sensor calibrations by assuming first-pass success, and we have eliminated unnecessary background collections for the GEO-2 test campaign.

Finally, we are scaling back the trial period for GEO-2. Because GEO-1 was a first-of-a-kind satellite and ground system, we put it through a 60-day trial period. For GEO-2, we are planning a 30-day period since it is the second delivery and we already have a good understanding of the payload.

We also leveraged lessons learned from prior efforts for GPS IIF. We gained significant confidence in the structural integrity of the first three SVs, which allowed us to eliminate acoustic testing for SVs 4–12. This amounts to a savings of approximately 15 days in each subsequent production flow. Meanwhile, GPS III has reduced cycle time by 57 percent through test reduction, extensive engineering, and prototype use.

Our AEHF program office and Lockheed Martin evaluated the test program to identify potential efficiencies and reductions. This resulted in reduced SV single-line flow testing for bus, payload, and SV-level tests. We also eliminated vehicle-level anomaly detection and resolution testing, which can be run on the Networked AEHF System Test Bed Tool or payload engineering model.

Reduce Unnecessary + Costly Oversight

Along with the programmatic streamlining, we have found further efficiencies in human resource management. The program operating plan (POP) defines and describes for each program the interaction and information exchange between the government and contractor. Some highlights of the POP include reducing the frequency of formal meetings/ reviews and streamlining informal interactions between the government and contractor. The POP also identifies the core set of meetings, roles, responsibilities, and authorities for such meetings as well as requirements for informal government and contractor interaction.

With our WGS Program Office, we were able to reduce the number of required personnel by implementing a commercial-sector-like approach for the production of WGS 7–10. The Air Force deemed appropriate a commercial-like acquisition approach for the production of WGS 7–10 to account for the maturity of the production and acceptable Boeing plant. These seven government members have full access to Boeing data and meetings, but their primary role is risk identification.

This arrangement, along with closing Block II, allowed the government program office to reduce personnel by about 40 percent. Furthermore, using Boeing’s commercial processes will reduce production and government-specific reviews, such as program management and mission assurance reviews, to almost zero. The stable design of WGS affords us the flexibility to limit government oversight, which saves Boeing “standing army” costs while still delivering robust satellites.

Reduce Reporting Requirements

We have also significantly reduced reporting requirements from our contractors, which drives down costs. We have streamlined integrated baseline reviews to a one-day event and removed thresholds for variance reporting. Contractors now report only the variances they determine would have significant impacts on the contract.

Additionally, we greatly reduced the number of CDRLs from many of our programs.5 In order to make such reductions, we created the Data Accession List as a mechanism to deliver technical assessments and products to the government on an “as-needed” basis, maintained a streamlined list of programmatic-status CDRLs, monitored financial and small-business CDRLs for oversight, and focused on current needs so that we are not bound to outdated contractual obligations.

As a result, we reduced System Engineering and Integration CDRL items from 46 to nine for SBIRS. This allowed us to build up the flexibility to tackle emerging needs with decision-quality information. For AEHF-5/6, we reduced the total number of CDRLs by 48 percent and reduced government-approved CDRLs by 44 percent from AEHF-4. And for GPS III, we reduced CDRLs from 115 to 20.

Introduce Competition

Introducing competition is another way we are making our space systems more affordable. Full and open competition consistent with the Better Buying Power initiatives of the Office of the Secretary of Defense for Acquisition, Technology, and Logistics was a major driver in cost reduction for our GPS Control Segment sustainment contract award. We were able to use the lowest priced, technically acceptable source-selection strategy and select a firm-fixed-price contract because the system is in the operations and sustainment phase of its life cycle, and therefore the requirements are well understood. As a result, the actual contract award came in at $119 million, a savings of $68 million from the original government budget / cost estimate of $187 million.

We also held a competitive source selection for the Command and Control System–Consolidated (CCS-C) Production and Sustainment Contract (CPASC). Including CCS-C production for WGS 6–9, production for AEHF 3–5, development studies, and sustainment, our estimate for the CPASC was $199 million. However, after we used predominantly fixed-price-incentive contract line-item numbers, set ceiling prices on those line-item numbers to prevent overrun expenses to the government, and provided a 50/50 share ratio in cost-incentive arrangement, the competition led to a six-year negotiated contract price of $133 million, including options. That’s a savings of $66 million.

Consolidate Baselines + Contracts

We have been working to increase efficiencies through consolidating baselines and contracts. For our SBIRS ground system, we initiated Increment 2 Completion (Inc2C) in November 2012 for a full groundprogram baseline, restructuring the Block 10 baseline into four incremental deliveries with one Program Executive Officer Certification and Operational Acceptance event for a primary operations center (MCS-2) at Buckley AFB, Colorado, and a backup operations facility (MCSB-2) at Schriever AFB, Colorado.6

Under the program, we have consolidated SBIRS satellite command and control operations from Buckley AFB (Defense Support Program), Schriever AFB (HEO1 and HEO2), and the Interim Test Center (GEO1 and GEO2) into MCS-2 and MCSB-2. This has allowed us to combine ground and system test activities early in the testing process and streamline test and verification processes in concert with the Air Force Operational Test and Evaluation Center. Moreover, the incorporated simulator data allow earlier defect discovery within an operational environment, and we can increase use of flight-test assets for more robust system test resources.

Another major consolidation effort is the Consolidated Orbital Operations Logistics Sustainment (COOLS) contract, which will yield efficiencies by merging existing sustainment efforts supporting the Defense Satellite Communications System, Milstar, and AEHF constellations under a single contract. As the contractor shares component experts across an even broader range of programs such as Military SATCOM, SBIRS, and GPS, we expect to gain even more efficiencies. Through these efficiencies and scope reductions, the team predicts a 35 percent cost reduction by the end of the five-year COOLS contract.

We are currently experiencing significant duplication of work because no single contractor is responsible for total system performance of the Eastern Range and Western Range, and the government must intervene whenever contractors work together.7 To eliminate some of that duplication, we are partnering with the 45th and 30th Space Wings to select a single contractor for a consolidated Launch and Test Range System (LTRS) Integrated Support Contract (LISC) Operations, Maintenance, and Sustainment Contract (LISC OM&S) of more than $2.5 billion for 10 years. This effort is designed to enhance mission effectiveness and generate cost efficiencies at both the Eastern Range and Western Range, which allows us to reinvest the savings in the ranges.

Under the LISC, one contractor will be required to keep the range “green” (or “go for launch”). The government will hold the single contractor accountable to meet system metrics, and the contractor will bear the risk if the system does not perform. This construct allows the selected contractor to optimize manpower to meet mission needs and increase profits while providing a system that meets the government’s requirements. We released the LISC OM&S request for proposal to industry in late March this year, began source selection on 30 May 2013, and expect to award the contract the second quarter of 2014.

Planning For The Future

All of our ongoing efforts are allowing us to continue providing current capabilities for about another decade. But what happens after that? As the current congested, contested, and competitive space environment continues to evolve, we will also have to evolve our architectures to maintain space superiority. The following are the main concepts that are more fully discussed in an article I coauthored entitled “Space: Disruptive Challenges, New Opportunities, and New Strategies,” published in Strategic Studies Quarterly8.

Traditionally, our strategy has been to load multiple missions onto every spacecraft because the cost of launch has been prohibitively expensive. Now with robust constellations of satellites already set in place and a thriving commercial medium-launch market at hand, we are looking to exploit the new commercial trade space by reducing the size of our missions and spreading them across multiple launches. Doing so is beneficial to us in many ways. First, the up-front costs are significantly lower for us. Traditional gargantuan satellites can weigh up to 10,000 pounds, including spacecraft and fuel at launch. Of course, the more size, weight, and power a satellite requires, the heftier the overall price tag. By using much smaller free-fliers or payloads that are attached to host space vehicles, we can drastically reduce costs typically associated with traditional programs. This affords us both the flexibility to make quick-turn decisions when faced with unforeseen circumstances at the action level instead of waiting for approval up the chain and the ability to send updated technology into space more frequently.

We can further cut costs by employing commercial buses to leverage the commercial market. The government has traditionally emphasized use of unique buses for each launch, and the maintenance and repair costs of several one-of-a-kind buses have been monumental. To be sure, we had to develop first-of-a-kind spacecraft more out of necessity than preference in the early days of space exploration, but now we have a competitive commercial market of spaceflight-proven buses that we can essentially buy off an assembly line. Eliminating nonrecurring engineering along with the expensive knowledge legacy and maintenance that go along with these unique buses will lead to huge cost savings for us.

Leveraging the international space environment with cooperative programs and shared capabilities can further reduce cost while strengthening international relationships. As mentioned above, the WGS-6 and WGS-9 international arrangements allow us to get more assets into space, and we collectively benefit from increased data bandwidth. Another example is the Constellation Observing System for Meteorology Ionosphere and Climate (COSMIC), a joint Taiwan-US science mission for weather, climate, space weather, and geodetic research. The COSMIC payload science data are routinely downloaded every orbit and have demonstrated their value for operational weather forecasting, hurricane forecasting, and investigations of the atmospheric boundary layer.

Due to the success of the first COSMIC, Taiwan and the United States have decided to move forward with COSMIC-2, a follow-on mission that will launch six satellites into low-inclination orbits in early 2016 and another six satellites into high-inclination orbits in early 2018. The US Air Force will provide two space weather payloads that will fly on the first six satellites of COSMIC-2, and Taiwan will help with costs of the overall program, resulting in about 50/50 cost sharing between Taiwan and the United States for COSMIC-2.

Hosted payloads offer us another alternative to save up-front costs and to leverage the competitive and congested aspects of space. Because we are operating in such a crowded manifest, partnerships with both commercial companies and other nations will become increasingly important to access the spectrum we need. By reducing the size of our missions and riding on commercial or international hosts as payloads, we can multiply the opportunities we have to gain access to space.

Cape Canaveral Air Force Station, Florida (May 24, 2013) – In the second launch in just nine days for the U.S. Air Force, United Launch Alliance (ULA) successfully launched a Delta IV rocket carrying the fifth Wideband Global SATCOM (WGS-5) satellite at 8:27 p.m. EDT today from Space Launch Complex-37. Wideband Global SATCOM provides anytime, anywhere communication for the warfighter through broadcast, multicast, and point-to- point connections. WGS is the only military satellite communications system that can support simultaneous X- and Ka-band communications. Photo by Pat Corkery, United Launch Alliance.

As a corollary to cost, resiliency is driving us to consider alternatives to traditional ways of accessing space. Taking new orbits and nonspace systems is part of the new equation when examining potential architectures. For example, we are starting to examine orbits that are higher in altitude and more inclined than traditional orbits as space becomes more congested and contested. We are also looking at ways to improve the timeliness of our command and control systems to quickly send commands and adjust our spacecraft posture to known threats or space debris. These new options require the flexibility that disaggregation allows in order to be feasible. Moreover, distributing our assets improves our resiliency to attacks and system failure by not putting “all of our eggs in one basket.”

Because our past strategy has been to load multiple missions onto every spacecraft, if one of our multimission spacecraft goes down due to either technical failure or adversarial attack, all of those capabilities that our nation relies on will be lost. Distributing those missions across several platforms will ensure that we can continue to count on other capabilities should a spacecraft carrying one of our missions fail. Additionally, placing missions on buses hosted by commercial or international partners can really complicate an adversary’s decision to attack our capabilities.

Lastly, we need to develop new and robust architectures based on new technology and the foundational work we’ve conducted to develop methods of assessing future systems. For instance, the wide-field-of-view technology proven by the successful Commercially Hosted Infra- Red Payload technology demonstration gives us the ability to detect multiple objects simultaneously and increases detection accuracy. We need to leverage such technological advances along with improved processing time and improvements in cyberspace to continue to be the best Air Force in the world.

References

1Milstar provides the president, secretary of defense, and the U.S. armed forces with assured, survivable SATCOM with low probability of interception and detection. The objective of the Milstar program was to create a survivable, secure, nuclear-survivable, space-based communication system, which was considered a top national priority during the Reagan administration. There are five operational Milstar satellites. The first two satellites (Milstar I) carry a low-data-rate payload that can transmit 75 to 2,400 bits per second of data over 192 channels in the extremely high frequency range. Encryption technology and satellite-to-satellite cross-links provide secure communications, data exchange, and global coverage. The other three satellites (Milstar II) carry both low-data-rate and medium-data-rate payloads. The latter can transmit 4,800 bits per second to 1.544 megabits per second of data over 32 channels. The higher data rates allow the user to transmit large amounts of data in a short period of time.

2 L1 C/A is the legacy civil signal, which will continue broadcasting in the future. Users must upgrade their equipment to benefit from the new signals. The military precise (P) code is encrypted by the military—using a technique known as antispoofing—and is available only to authorized personnel. The encrypted P code is referred to as the Y code. Civilian GPS receivers use the C/A code on the L1 frequency to compute positions—although high-end, survey-grade civilian receivers use the L1 and L2 frequencies’ carrier waves directly. Military GPS receivers use the P (Y) code on both L1 and L2 frequencies to compute positions. L5 is the third civilian GPS signal, designed to meet demanding requirements for safety-of-life transportation and other high-performance applications. L5 is broadcast in a radio band reserved exclusively for aviation safety services. It features higher power, greater bandwidth, and an advanced signal design. L2C is the second civilian GPS signal, designed specifically to meet commercial needs. When combined with L1 C/A in a dual-frequency receiver, L2C enables ionospheric correction—a technique that boosts accuracy. Civilians with dual-frequency GPS receivers enjoy the same accuracy as the military (or better). For professional users with existing dual-frequency operations, L2C delivers faster signal acquisition, enhanced reliability, and greater operating range. L2C broadcasts at a higher effective power than the legacy L1 C/A signal, making it easier to receive under trees and even indoors. The Commerce Department estimates that L2C could generate $5.8 billion in economic productivity benefits through the year 2030.

3Unit-level thermal cycle and powered vibration tests screen hardware for design and workmanship issues by simulating the on-orbit operating environment that the units will experience. On-orbit performance of the GEO-1 space vehicle and ground test performance of the GEO-2 space vehicle demonstrated the sound design of the units under test and thereby provided confidence that the additional thermal cycles and powered vibration tests could be eliminated. This would save cost with a very modest but acceptable increase in risk for workmanship issues that might not be discovered until later at a higher level of assembly.

4Similar to an aircraft assembly line, the GPS IIF pulse line efficiently moves a satellite from one designated work area to the next at a fixed rate. The GPS pulse line can accommodate four satellites at any given time. Wait time between tasks is reduced or eliminated by staging necessary parts and tools at the point of use at each workstation, creating a smooth process flow. Along the pulse line, satellites flow to work centers dedicated to four manufacturing stages: vehicle assembly, initial test, thermal-vacuum testing, and final test. The line delivers one SV to storage every two to three months.

5The CDRL includes authorized data requirements for a specific procurement that forms part of a contract. It is comprised of either a single DD Form 1423 or a series of such forms containing data requirements and delivery information. The CDRL is the standard format for identifying potential data requirements in a solicitation and deliverable data requirements in a contract.

6Increment 2 completion represents the ground program baseline that consolidates operations of the Department of Defense’s overhead persistent infrared satellite constellation supporting missile warning, missile defense, technical intelligence, and battlespace awareness missions. The constellation consists of three major systems: the Defense Support Program, SBIRS GEO satellites, and SBIRS HEO payloads. Increment 2 completion will relocate ground operations for each of these systems from their individual locations known as the mission control station (MCS) at Buckley AFB and the MCSB at Schriever AFB. Additionally, the Increment 2 baseline delivers a satellite command and control, mission processing, and external reporting architecture that allows for data fusion and fast, accurate reporting on infrared events around the globe.

7The Eastern Range (ER) and Western Range (WR) are the national security space rocket ranges for the United States. The ER supports missile and rocket launches from the two major launch heads located at Cape Canaveral Air Force Station and the Kennedy Space Center, Florida. It is managed by the 45th Space Wing. The WR supports the major launch head at Vandenberg AFB, California. Managed by the 30th Space Wing, the WR extends from the West Coast of the United States to 90˚ east longitude in the Indian Ocean.

8Lt Gen Ellen Pawlikowski, Doug Loverro, and Col Tom Cristler, “Space: Disruptive Challenges, New Opportunities, and New Strategies,” Strategic Studies Quarterly 6, no. 1 (Spring 2012): 27–54, http://www.au.af.mil/au/ssq/2012/spring/spring12.pdf.

About the author

Lieutenant General Pawlikowski is commander of the Space and Missile Systems Center, Air Force Space Command, Los Angeles AFB, California. She is responsible for more than 6,000 employees nationwide and an annual budget of $10 billion. As the Air Force program executive officer for space, General Pawlikowski manages the research, design, development, acquisition, and sustainment of satellites and the associated command and control systems.

This article is courtesy of the Air and Space Power Journal

http://www.airpower.au.af.mil